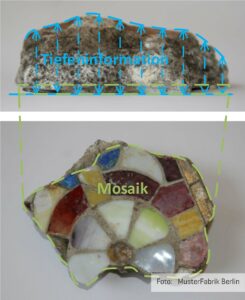

Our novel automated scanning systems for 2.5 D objects enable a stock-protecting and time-efficient digitization of specific fragile three-dimensional objects with at least one flat surface. These can be, for example, wall plaster or mosaic fragments, which have a flat surface (carrying a motif) on one side and a raised surface (carrying plaster) on the other.

Dual-sided capturing of objects in a single scanning pass that is gentle on the inventory

Our automated 2.5-D scanning systems capture the front and back of the objects in 2-D as well as the raised back of the objects in 3-D in one scan pass. An elevation map is then automatically generated from the 3-D image. The 2-D images of both sides of the objects are automatically cropped with pixel accuracy during image acquisition.

Generating accurate images of the originals

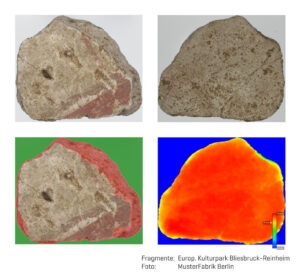

Our automated 2.5-D scanning systems generate true-color and shadow-free images of the originals that are sufficiently geometrically accurate on the motif level. The digitized images are automatically cropped in the raw scans during image acquisition. This includes both the automatic detection of the outer object border and the automatic masking of all image areas of the (motif-related) flat surfaces.

Time-efficient object capturing

Our methodology for 2.5-D digitization combines the advantages of 2-D and 3-D processes in a reasonable and efficient way by capturing only the most meaningful features “from both worlds”. In this way, all information of the 2-D images is enriched by the depth information that may be relevant for further processing, which is indicated by the term 0.5-D. Our approach thus differs from the usual 3-D approach in principle, since no complete 3-D acquisition of the objects has to be made. This eliminates both the often very time-consuming acquisition and the downstream complex extraction procedures of 3-D object features.

Sequence of the scanning process for 2.5-D digitizing

© MusterFabrik Berlin

Top: 2-D incident light images front and back.

Bottom: Mask image front and elevation map back

For digitization, the objects are placed in the scanner on a scratch-resistant glass plate with the flat (motif) surface facing down. In an automatic process, the front and back of the objects are then captured in 2-D and the raised back of the objects in 3-D, all in single scan pass.

After all image data has been captured, the individual images are automatically scaled to a uniform resolution and masked with pixel accuracy in the raw scan. An elevation map is also automatically generated from the 3-D image. For geometrically more complex cases, an additional laser illumination can be used to make the transitions between the motif and plaster visible and to automatically mask the flat motif planes.

Since the objects do not have to be moved during the scan, the method is particularly suitable for fragile materials, where repeated manual handling would lead to further loss of substance.