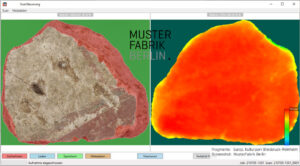

Our automated 2-D and 2.5-D scanning systems are operated using scanner control software developed by us. The software has a graphical user interface and encapsulates all device-specific hardware interfaces. This provides the operators of our automated scanning systems with a uniform front end for performing digitizing tasks and assigning meta information.

User Interface of the Control Software

The user interface of our scanner control software includes the interactive viewer components developed by us, which are also used in our automated assistance systems. The viewer components enable a two-sided and infinite zoom display of raw scans and pixel-precisely cropped digitized images. The maximum available sharpness of detail of the display is limited only by the resolution used for digitization. For navigation within large raw scans, the displayed image section can be interactively shifted and scaled as desired. This is possible even with very large images (e.g. 60 x 45 cm²) with a scan resolution of 1,200 dpi without latency (“jolt-free”).

With the help of our scanner control software, the digitized files can already be flexibly assigned task-specific meta information during acquisition. This can be done either interactively via the user interface or automatically by importing data that is available for the material to be digitized, for example in an external data source.

Distributed workflow to increase scan throughput

Our scanner control software offers various options that can be used to increase scan throughput without the need to purchase an additional scanning system. Depending on the task at hand, the execution of the individual process steps digitization, quality control and metadata assignment can be organized in a divided workflow.

In the so-called offline mode of the control software, for example, previously saved scan runs of a scan job, i.e. those dating back to any time, can be opened and edited at a PC workstation without a scanner interface. This can be used both for subsequent identification and marking of incorrectly digitized objects (dog-ears, tears, etc.) within a raw scan and for offline assignment of metadata for individual or all objects of a raw scan.

For example, when using a scanning system (with a connected scanning workstation) and two additional PC workstations connected via network, each running the scanner control software, it is possible to implement the following digitization workflow to increase scanning throughput:

- Process step at a PC workstation: import of inventory metadata from external data sources and/or interactive capture of global metadata for entire scan batches and/or individual scan jobs

- Process step at the scan workstation: digitization of all objects of all scan jobs of a scan batch

- Process step at a PC workstation: Quality control of all digitized images of individual scan jobs and, if necessary, marking of incorrectly digitized objects for which a new scan is to be performed (at the scan workstation), as well as assignment of specific metadata for individual digitized images of the current scan job.

Depending on the task at hand, it may be more effective for smaller object quantities to perform the 3rd process step (quality control and metadata assignment) directly at the scan workstation. With very large object quantities, on the other hand, splitting the 3rd process step can increase the scan throughput by performing the two sub-tasks of quality assurance and metadata assignment at two separate PC workstations (a total of three PC workstations and one scanning workstation are then required for digitization).

Basic workflow of the control software (excerpt)

- Initializing a new scan batch or a new scan job

– (automatic) import of inventory metadata and/or

– interactive input of metadata by the operator - Image acquisition of the current scan pass

– automatic multichannel double-sided acquisition of all objects in one scan pass

– automatic detection of all digitized objects (“bounding box”)

– automatic cropping of the individual digitized files (“pixel-precise masking”) - Visualize and prepare the digitized files of the current scan run

– double-sided display of the raw scans and/or the cropped digital copies

– optional: display of different channels

– optional: control/correction of asset metadata

– optional: assignment of metadata for individual digitized files

– optional: re-scan of the current scan pass - Saving the results of the current scan run

– Automatic conversion of scan results into common file formats

– automatic file storage in a defined directory structure (local and/or network)

– optional: convert and save additional channels and/or raw scans - Resume or Exit

– new scan pass within the current scan batch, or

– new scan batch within the digitizing task, or

– finish the digitization task